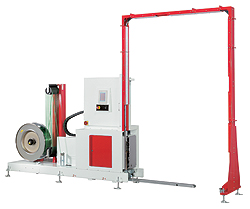

TP-733H Castor III

The enhanced TP-733H provides accurate strapping output on all natural-sized loads with consistent performance. It can be used in a line or as a stand-alone packing station. It maximizes the productivity and minimizes the production cost for users. Designed for simple and quick connection to the master control system , TP-733H can easily fit in various end-of-line packaging sectors. It's your best choice for fully automatic operation in various applications, including palletized products, home appliance, bricks & blocks, etc.

Main Features

TP-733-SH strapping head with German-made DC brushless motor technology. Works with PP and PET strap for tension up to 320 kg. Friction weld sealing technology.

Siemens PLC and HMI

Index strapping head that moves towards the package with stroke up to 300 mm

Strap guide arm to help precise strap position on the load

Safety rack

Other Features

Adjustable sealing and cooling time

Swivel dispenser set

Preprogram of 10 different strapping patterns

Options

Floating head

Free standing operation desk

HMI and PLC mounted on the opposite side

3 color light tower with low strap sensor

Program selection with remote control

Uplifted support

| Technical Data | |

|---|---|

| Strap type | PP or PET |

| Strap width | 12 mm, 15.5 mm or 19 mm |

| Strap core size | 406 mm |

| Tension range | up to 320 Kg (standard) 20-120 Kg (option) |

| Capacity | Up to 60 pallets/hour (3 parallel strap) (depends on package dimensions) |

| Minimum Strapping Height | 240 mm above the floor 160 mm above conveyor surface |

| Electrical requirements | 220V/380V/400V/415V 50/60 Hz 3PH |

| Pneumatic source & air consumption | 6 bar - 7.1 liter/cycle |